In the LED display industry, the quality of LED lamp beads is crucial. Since each square meter of an LED display module can house thousands to tens of thousands of these beads, they play a significant role in determining the overall display performance and directly affect audience perception.

Furthermore, LED lamp beads account for a substantial portion of the total cost, typically ranging from 30% to 70%. This highlights the importance of understanding how to evaluate the quality of LED lamp beads for all users of LED screens.

1. Impact of LED Lamp Beads on Screens

1.1 Viewing Angle

The viewing angle of an LED display is largely influenced by the angle of the LED lamp beads. Displays mounted on high structures may require wider viewing angles. It’s essential to note that a conflict may arise between viewing angle and brightness; a wider viewing angle could lead to reduced brightness. Therefore, the selection of LED lamp beads should align with the specific application requirements.

1.2 Brightness

1. The brightness of the LED is a key factor in determining the overall brightness of the LED display. Generally, higher brightness levels provide more content possibilities and can also help save on power consumption while maintaining stable performance.

2. Typically, narrower viewing angles correspond to brighter LED lamp beads. A minimum viewing angle of 100° is recommended for adequate perspective, but a balance between brightness, viewing angle, and cost is necessary.

1.3 Failure Rate

A full-color LED display is made up of hundreds of thousands of red, green, and blue pixels. The malfunction of even one color can negatively impact the overall visual quality of the display.

1.4 Anti-static Capability

LED are semiconductors and are sensitive to static electricity, which can lead to failures. Strong anti-static properties are crucial for extending the lifespan of the display; typically, the failure voltage in human body mode tests should be no less than 2000V.

1.5 Lifespan

The theoretical lifespan of LED lamp beads can reach up to 100,000 hours, surpassing that of other components in LED display panels. With suitable operating currents, effective PCB thermal design, and stringent production standards, LED can become one of the most durable parts of LED displays.

1.6 Attenuation Characteristics

Variations in brightness attenuation among red, green, and blue LED can lead to color inconsistencies within the display, often referred to as “color blooming.” High-quality LED components can effectively manage brightness decay.

Over time, LED display modules may experience brightness reduction and color inconsistencies, commonly described as “blurry screens,” primarily due to LED brightness attenuation.

1.7 Size

The size of LED lamp beads affects the resolution of the LED display. For instance, 5mm ellipsoidal LED are typically used for outdoor screens above P16, while 3mm LED suit P12.5, P12, and P10 displays. SMD LED like 3528 are generally used for P6 and P8 indoor displays, whereas 2020 SMDs are common in P2 and P3 indoor screens.

As the size of the LED increases while maintaining the same dot pitch, the display area expands, which can reduce the black area and diminish contrast. Conversely, reducing the size of the LED can enhance contrast.

1.8 Consistency

The uniformity of brightness and wavelength among the LED is vital for achieving consistency in brightness, white balance, and chromaticity across the entire display.

As the LED lamp beads are angular, the full-color display will exhibit varying brightness levels from different viewing angles. Therefore, the consistency of the angles for the red, green, and blue LEDs is essential for maintaining accurate color representation. Achieving such consistency requires scientific design and high-quality raw materials.

2. Guidelines for Selecting LED Lamp Beads

Understanding the impact of LED on display performance underscores the importance of selecting high-quality LED lamp beads. Here are some tips for selecting the right products:

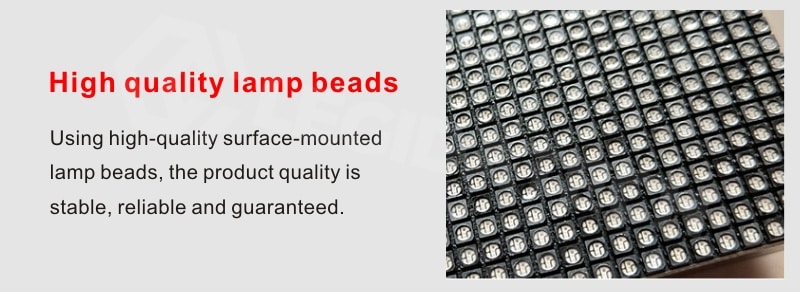

Inspect the solder joints. Manufacturers usually employ SMT SMD processes and use solder paste and reflow soldering techniques.

Ensure the cleanliness of the LED surfaces. When using the SMT process, the surfaces should be free from excessive impurities and contaminants.

Evaluate the chip quality. The chip is a critical element determining the overall quality of the lamp beads. Typically, more stable chips lead to brighter LEDs and better heat dissipation.

Assess the adhesive used. Quality products often use imported glue, ensuring that lamp beads maintain their shape under pressure, while inferior products may deform or crack.

Consider the packaging technology. High-quality LED lamp beads exhibit consistent color uniformity, which is closely linked to advanced machinery and equipment.

Check for color consistency. Poor-quality lamp beads may display uneven brightness or noticeable dark areas.

Choose reputable suppliers. Opting for well-regarded manufacturers like Cailiang can mitigate the risks of performance issues.

Conclusion

This article outlines the various impacts that LED lamp beads can have on LED screens and provides guidelines for assessing their quality. In summary, selecting reliable LED lamp beads is a fundamental step in ensuring optimal LED display performance, as they influence every aspect of the visual output.

FAQs

1. What is an LED Lamp Bead?

An LED lamp bead serves as the core component of a high-power LED module. Its design allows for installation onto a heat-dissipating surface, efficiently transferring excess heat away from the LED. Explore our extensive range of aluminum base plates, heatsinks, and related accessories for LED beads.

2. Why Are LED Lamps Considered Expensive?

The pricing of LED lamps is influenced by supply and demand dynamics, but it also stems from the advanced technology utilized, the multiple components required for assembly, and the inclusion of pricier materials such as aluminum.

3. Why Are LEDs Superior to Traditional Lamps?

LED holiday lights not only consume significantly less energy, but they also offer several additional benefits:

- Safety: LEDs operate at a much cooler temperature compared to incandescent bulbs, minimizing the chances of burns or fire hazards.

- Durability: Constructed with epoxy lenses rather than fragile glass, LEDs are far more resistant to breakage, making them a sturdier option overall.